5 layer Paper Poly Foil

Price 300 INR/ Kilograms

MOQ : 2.5 Tons

5 layer Paper Poly Foil Specification

- Paper Type

- Kraft Paper or Specialty Paper

- Pulp Material

- Wood Pulp

- Pulp Type

- Virgin Pulp

- Style

- Laminated Multi-Layer

- Size

- Customizable (Standard widths available)

- Thickness

- 80-180 microns (customizable)

- Weight

- As per customer requirements

- Width

- 200 mm 1200 mm

- Moisture

- <8%

- Bursting

- High Bursting Strength

- Color

- White, Silver, Brown or as required

- Coating

- PE and Foil Layer

- Coating Side

- Single or Double Side

- Coating Material

- Polyethylene (PE) & Aluminum Foil

- Density

- Gram per cubic centimeter(g/cm3)

- Tightness

- Tight Sealing Capability

- Feature

- Moisture Proof, Durable, Heat Sealable, Multi-Layer Protection

- Compatible Printing

- Gravure, Flexographic, Offset

- Use

- Food Packaging, Pharmaceutical Packaging, Industrial Laminates

- Customization

- Yes

- Shape

- Roll, Sheet

- Roll Length

- Customizable as per demand

- Tensile Strength

- Enhanced

- Temperature Resistance

- Up to 120°C

- Aluminum Foil Gauge

- 7 to 12 micron standard

- Environment Compliance

- Food Grade, ROHS compliant

- Shelf Life

- Long life for packed goods

- Number of Layers

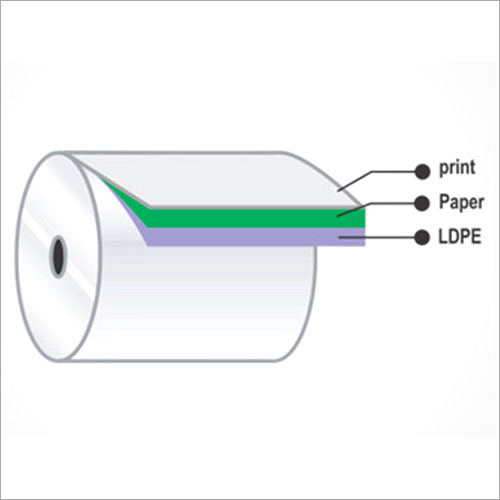

- 5 (Paper/PE/Foil/PE/Paper)

- Printability

- High quality, multi-color printing support

- Odor Barrier

- Excellent

- Surface Finish

- Glossy or Matt

- Application

- Flexible Packaging, Sealable Lids, Pouches

5 layer Paper Poly Foil Trade Information

- Minimum Order Quantity

- 2.5 Tons

- Supply Ability

- 500 Tons Per Month

- Delivery Time

- 1-3 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Roll Form

- Main Domestic Market

- All India

- Certifications

- ISO Certified

About 5 layer Paper Poly Foil

We are a trusted manufacturer of 5 layer Paper Poly Foil in the market. It is extensively used to pack medicines because of its qualitative texture and strength. 5 layer Paper Poly Foil can form into different packing styles to fit the demands of the customers. We offer this at highly economical rates.

Exceptional Barrier Protection

This 5 layer laminate provides superior moisture, oxygen, and odor barrier properties, essential for maintaining the freshness of packaged goods. The aluminum foil layer, available in 7-12 micron standard gauge, works in tandem with PE and specialty papers to ensure contents remain uncontaminated and unaffected by external conditions. The structure supports both glossy and matt surface finishes as required.

Flexible and Customizable Design

Designed for versatility, this material can be supplied as rolls or sheets, with customizable thickness (80-180 microns), widths (200 mm - 1200 mm), and roll lengths tailored to specific demands. Customers can specify the paper type, color, and coating requirements, enabling bespoke packaging solutions for various industries, including food and pharmaceuticals.

Advanced Printability and Aesthetics

The product's print-friendly surface enables high-quality, multi-color branding using gravure, flexo, or offset technologies. This ensures your packaging stands out on shelves while maintaining the integrity and durability needed for industrial or retail use. Specialty papers and customizable finishes further enhance the product's visual appeal and functionality.

FAQ's of 5 layer Paper Poly Foil:

Q: How is the 5 layer Paper Poly Foil manufactured and structured?

A: This laminate consists of five layers: Paper, Polyethylene (PE), Aluminum Foil, another layer of PE, and a final layer of Paper. Each material is bonded through a precise laminating process to create a high-strength, multi-layer protection system.Q: What are the primary applications for the 5 layer Paper Poly Foil?

A: It is widely used in flexible packaging, sealable lids, and pouches, particularly for food and pharmaceutical products. Its excellent barrier properties and durability also make it suitable for industrial laminates.Q: When should I choose a matt or glossy finish for my packaging needs?

A: A matt finish is ideal for a premium or sophisticated appearance, while a glossy surface offers vibrant color rendering and higher shelf appeal. Both finishes provide equal protective qualities and can be selected based on aesthetic or branding requirements.Q: Where is this product compliant for use and does it meet food safety standards?

A: The laminate is manufactured in India and is compliant with food-grade and ROHS standards, making it safe and suitable for food and pharmaceutical packaging globally.Q: What advantages does this multi-layer structure provide compared to single-layer packaging?

A: The five-layer construction offers enhanced tensile and burst strength, excellent moisture and odor barriers, heat sealing capability, and long shelf life for packed products, outperforming single-layer alternatives in protection and durability.Q: How customizable are the size, thickness, and print options for this product?

A: Sizes, thickness (80-180 microns), widths, colors, and finishes are fully customizable. It supports high-quality, multi-color printing using gravure, flexographic, or offset processes to match specific branding or functional requirements.Q: What is the recommended process for sealing and converting this packaging material?

A: The material is compatible with standard heat sealing equipment and is easy to convert into rolls, sheets, pouches, or lids as needed. Its tight sealing capability ensures product integrity during storage and transit.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Multilayered Polycoated Films Category

3 Layer Paper Poly Foil

Price 300 INR / Kilograms

Minimum Order Quantity : 2.5 Tons

Shape : Roll Form

Treatment : Coated

Width : 5001000 Millimeter (mm)

Foil Type : Roll

4 Layer Paper Poly Foil Poly

Price 300 INR / Kilograms

Minimum Order Quantity : 2.5 Tons

Shape : Roll Form

Treatment : Coated

Width : 5001000 Millimeter (mm)

Foil Type : Sheet

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese